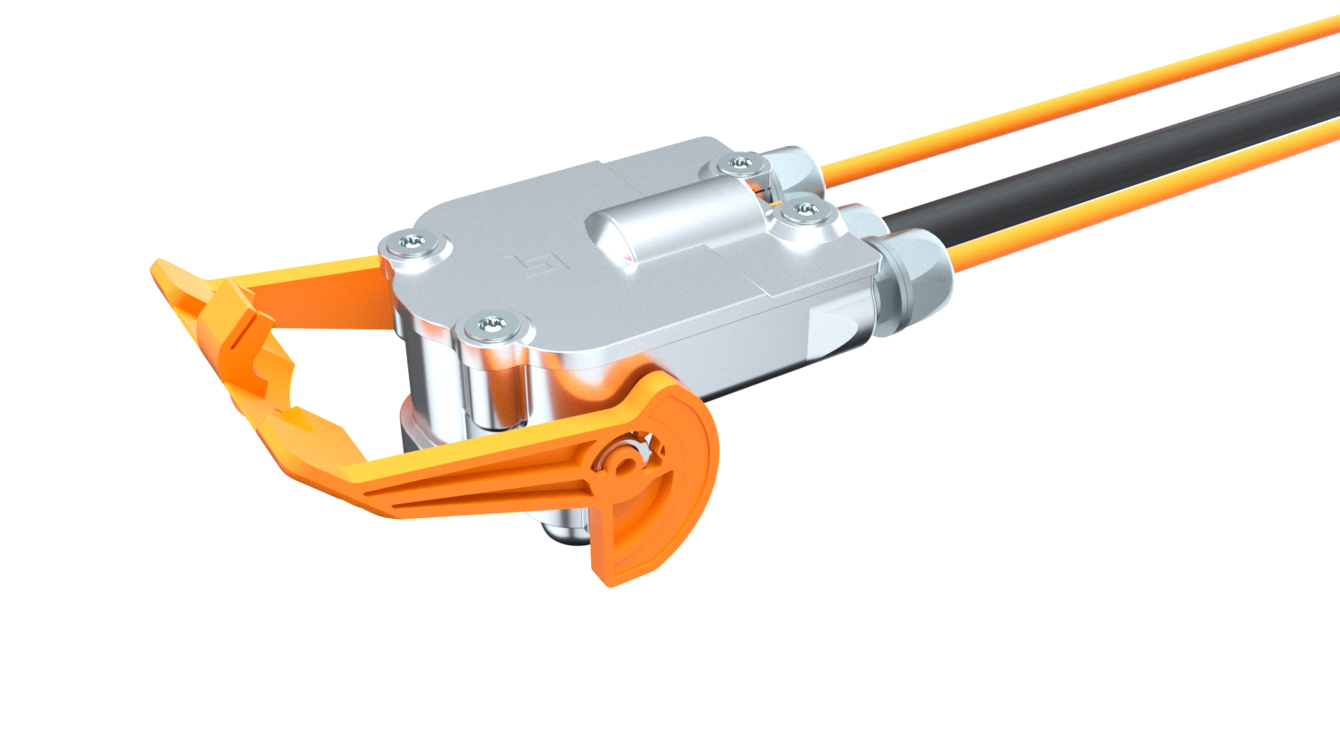

In the field of industrial engineering, where reliability and precision are crucial, standard connector solutions sometimes fall short. Complex applications can require tailored designs, specific cable lengths, and unique configurations to ensure optimal performance and seamless integration. This is where custom solutions for circular connectors and cordsets become essential.

binder, a leading provider of circular connectors, offers a comprehensive range of standard products designed to meet the diverse needs of industrial engineering applications. However, for projects requiring more specific features or bespoke configurations, binder goes beyond the standard.

Our vertically integrated business model, encompassing cable assembly, zinc die casting, circuit board production, and more, empowers us to deliver tailored solutions that meet the precise demands of industrial applications. We leverage our in-house capabilities to provide custom solutions that prioritize supply chain sustainability, flexibility, responsiveness, and self-sufficiency. These strengths allow binder to meet specialized customer demands with precision and efficiency.

Key Advantages of Custom Connectors for Industrial Applications

- Flexibility and Efficiency: Customized connectors provide engineers with the flexibility to design systems without constraints, ensuring the perfect fit for their specific needs. This eliminates the need for workarounds or compromises that can arise when using standard components.

- Optimized Performance: Tailored connectors and cordsets are designed to perform optimally within the intended application. Factors like cable length, shielding, and connector type are carefully selected to ensure signal integrity, minimize interference, and withstand harsh environmental conditions often found in industrial settings.

- Cost Effectiveness: While custom solutions may have a higher initial cost, they often lead to long-term cost savings. By optimizing performance and reliability, they reduce maintenance, replacement needs, and potential production disruptions.

Custom Connector Adjustments to Standard Products

For projects requiring minor modifications to standard items, binder offers flexible options such as custom cable lengths, shielding, pin counts, and cable colors. These adjustments ensure that even standard solutions can be optimized for specific applications. Customers can easily discuss their requirements with binder’s responsive customer service team to find the perfect fit for their needs.

binder's Approach to Customization

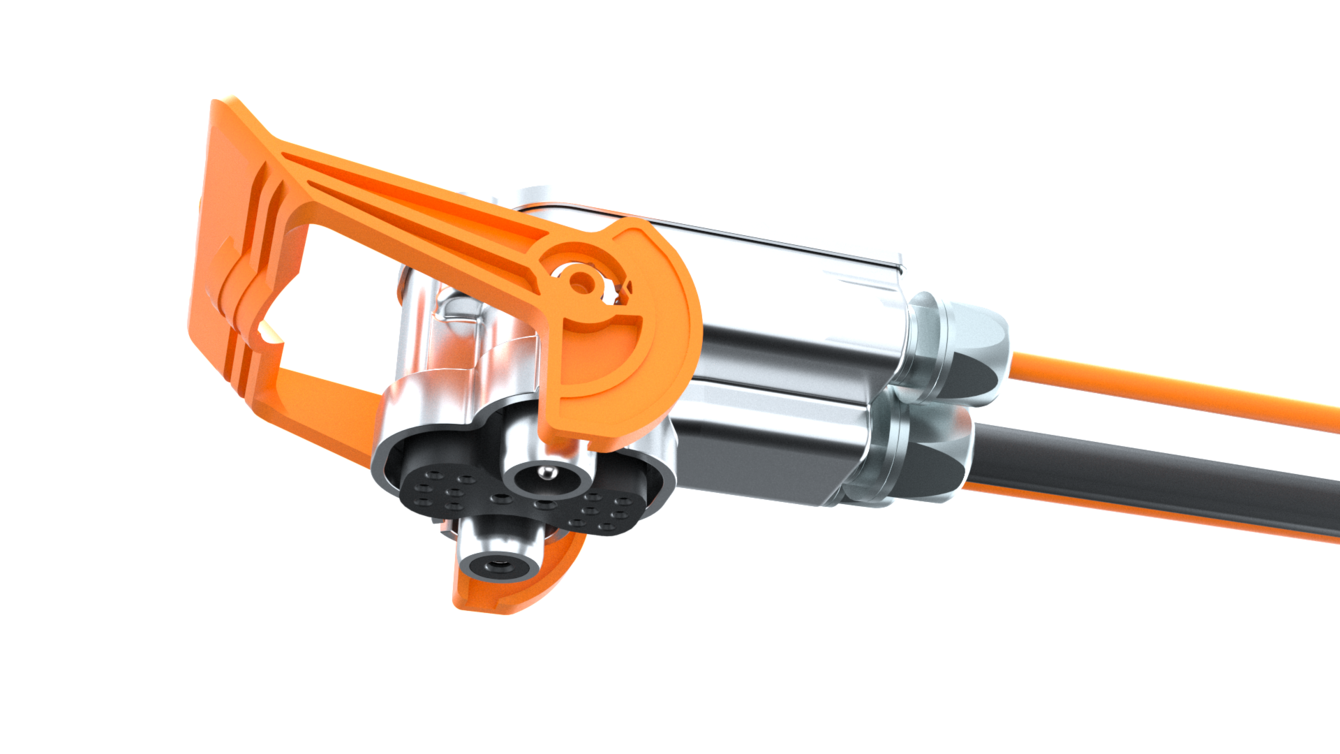

binder's commitment to customization goes beyond simply fulfilling orders. Our binder solutions business unit actively engage with customers to ensure their needs are met with precision and efficiency. Our approach to custom solutions starts with an idea. It begins with collaborative design from scratch, where binder's engineers work closely with customers, acting as consultative partners to fully understand their project requirements and design challenges. This ensures that the final solution aligns perfectly with the customer's vision and application needs. To facilitate evaluation and feedback, binder leverages advanced technologies and in-house capabilities to rapidly produce prototypes of custom connectors and other products. This allows customers to experience the design firsthand and provide valuable input before moving to full-scale production.

Our vertically integrated structure, encompassing everything from cable assembly to precision-turned parts, enables us to manufacture custom solutions with exceptional efficiency, translating to shorter lead times and cost-effective production, even for highly specialized designs. Throughout the entire process, quality and reliability remain paramount. binder subjects all custom solutions to rigorous testing, ensuring that the final product meets the highest industry standards and performs reliably in demanding industrial environments.

Custom solutions can be essential and non-negotiable in applications where reliability and precision matters. Especially in the demanding field of industrial engineering, this often can be the case. binder provides engineers with the design freedom to break free from the limitations of standard offerings and translate their unique ideas into reality. This allows for the optimization of designs for specific applications, achieving levels of performance that were previously unattainable.

Each industrial application presents its own set of challenges, and custom solutions offer a targeted approach to overcoming these obstacles. Whether it is addressing space constraints, ensuring signal integrity in harsh environments, or meeting specific performance requirements, custom connectors and cordsets provide tailored answers.

Furthermore, these solutions are designed to integrate seamlessly into existing systems, simplifying installation, reducing complexity, and minimizing the risk of compatibility issues. By optimizing design and construction for the intended application, custom solutions enhance reliability, minimize downtime, and contribute to a more robust and efficient operation.

Ultimately, offering custom connectors demonstrates binder's commitment to customer success. It fosters stronger, more collaborative relationships, with binder acting as a trusted partner in helping customers achieve their goals.

Reliability and Quality Assurance in Custom Connectors

binder’s reputation for high-quality, reliable products extends to its custom solutions. The company emphasizes transparency across the supply chain to optimize processes, from ordering and shipping to customer support. binder’s commitment to innovation, customer satisfaction, and quality standards ensures consistent excellence across our portfolio.

By combining advanced technical capabilities with a customer-centric approach, binder delivers innovative, custom-specific solutions that go beyond the standard product offering.

For technical inquiries or assistance, contact binder’s team at info@binder-connector.de and discover how binder can bring your vision to life.